Custom controllers for industrial systems, design, develop and Manufacture

Custom Keypad Graphic Overlays

Branding on the controller can attract a positive, image in the eyes of potential customer, it conveys a high level of professionalism. Using a custom overlay also makes the process easier to use for the operator, improves safety and also can reduce training times. Our custom overlay service ranges from customizing a standard overlay with a logo to a full custom overlay and metalwork.

Keypads are made using a reverse printed polycarbonate membrane, bonded to an aluminum backing plate. A printed circuit board is mounted under the aluminum plate and tactile switches protrude through the plate so that when pressed the embossed overlay lies flat against the plate preventing the operator from damaging the keypad switches. To make the overlay durable, the image is reverse printed, normally this is silk screen printed using solvent based inks and typically has around 6 colors. More colors can be printed using dot matrix printing with near photographic quality but with less durability as solvent inks are not used.

- Long life expectancy > 1,000,000 key presses

- Durable and tactile finish.

- Low cost to implement.

- Bright vibrant colors, scuff and UL resistant.

- Water and dust resistant.

- Matt or shiny finish.

- Highly attractive appearance and professional feel

- Tactile and easy to clean

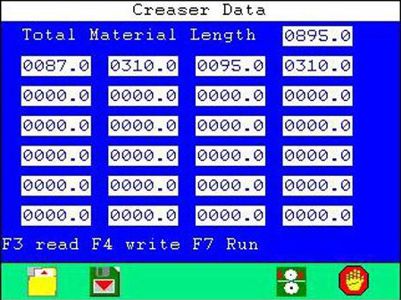

Custom Software Options

Custom software can be supplied as either a MAP template or as an executable program. Map is an easy to use programming language that has over 116 commands and some commands have 12 options. The benefit of a template is that it can be easily edited to suit special end user needs.

Creating menus and end user interfaces is very simple, many user interfaces can be written in less than 20 lines of code. Training is available and many people are able to program effectively after a very short course.

- >Easy to program, via Pull Down Menus

- No programming tools are needed.

- Program on or off line.

- Use or include G code.

- Graphical commands make user displays bright and easy to implement.

- Custom MAP commands available.

- Nesting commands.

- Extensive IO commands available.

Custom Panels, cabinets and moldings

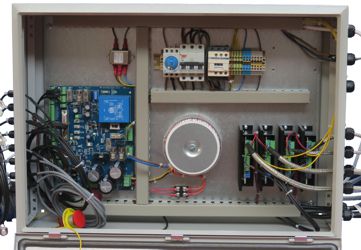

Making the front panel look good is important, Safety is vital, with this in mind controllers can be seamlessly built into control panels, along with Jog wheels, start stop buttons, emergency stop buttons, lamps, selector switches end many other items. Special cases are also available to differentiate your products from your competitors. Panels can have a special overlay as well making them look very professional. Panels can be supplied plug and play wired ready for use, all fully tested.

Like our Keypads panels may have a reverse reverse printed polycarbonate membrane, bonded to an aluminum backing plate. The controller can be built into the panel or there can be a slot in space for the controller. Special cabinets are also a popular option, these can be made to be included in a front panel or as a overhead, floor or arm mounted console. Many of our enclosures are designed in house using 3D CAD, or we can use an exiting design of your own.

- Durable enclosures with Overlay

- Ease of mounting, floor, arm or overhead.

- Low cost to implement.

- Bright vibrant colors, scuff and UL resistant.

- Water and dust resistant.

- Matt or shiny finish.

- Highly attractive appearance and professional feel

- Switches and buttons included reduces wiring costs

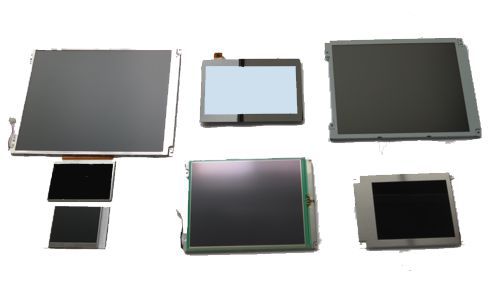

Choice of display technology

There is a wide selection of display options ranging from no display to a 12 full color touch screen". A display enhances the operator experience and is a good sales feature on most equipment. For ovens and other with less data to display there are also LED options. Most displays can be offered with a touch screen option. Normally this is a capacitive option although Resistive touch screens can be supplied.

For none touch screen options the display is protected by the thick Polycarbonate filter, this is also water resistant and dust proof. Touch screen options are better suited to cleaner environments as dirt and liquids can have an effect on the touch screen, the glass is also easier to break, this should be considered when a touch screen is used. Standard screen sizes include:

- 3.5" 320 * 240, 65536 colors

- 5.7" 320 * 240, 65536 colors

- 7" wide screen, 65536 colors

- 8" wide screen, 65536 colors

- 10.1" or 10.4" wide screen or VGA

- 12" wide screen

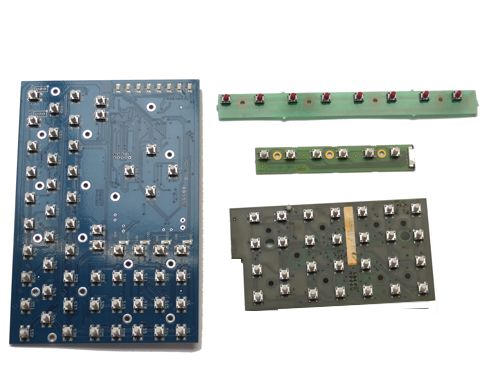

Custom Keypads

There is already a range of keypads and often a custom overlay is all that is needed. However sometimes a special Keypad is needed. Our service includes a full custom keypads these keypads include the ability to include keys around the display for example. It is also possible to have hybrid keypads where there is a keypad and a touch screen.

Reduce costs with a custom interface Card

Many machines have complex wiring that is expensive to undertake, the answer is to have a custom interface card. Each card is designed specifically for the machine or client making it easier to connect sensors, encoders, switches etc. Other services such as temperature control can be included on the interface card. Most analog, digital, power, signal conditioning etc can be implemented. This makes wiring more cost effective and reduces costs considerably.

Give us a list of the the blocks that your system needs, and we will look at custom interface card for you. The idea is to make the machine from a controller and a interface card that includes all the facilities that the machine needs, from power supplies to solid state relays. Signal services include pressure

Power services solid state relays- Temperature, pressure control etc.

- Wiring connectors.

- Logic inputs

- High Speed logic

- Logic outputs

- Power supplies etc.

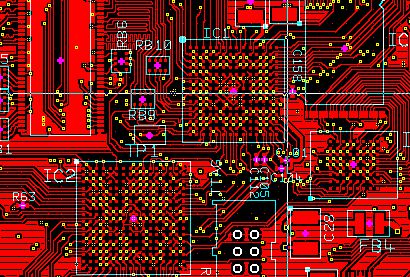

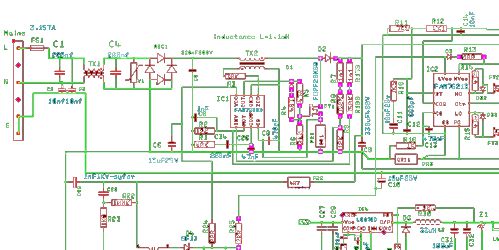

Custom Electronics Hardware

For applications such as Oven controllers it is feasible to make a full custom controllers. This involves the design of circuitry, circuit boards, FPGA and metalwork

Where there is reasonable volume it is often worth the investment in a custom designed hardware solution. Custom designs usually have software written for them but sometimes MAP can be adapted to suit the application and hardware. Custom hardware has many advantages over traditional controllers like PLCs, they are faster, more cost effective, safer, more reliable and provide a high level of copy protection security. Because of the custom nature of the design they are often less complex with fewer modules to suffer bad connections. Custom hardware also adds a high level of professionalism in the eyes of the customer. The service offered is a full design service using CAD software and includes schematic, PCB, firmware, software, custom fascias and casing. Typical applications that would suit custom hardware include:

- Oven and furnace controllers

- Tank contents control.

- CNC laser cutting machines

- Catering controls

- High Speed motion control

- Process controllers

- Medical devices

Electrical Boxes and Panels

Systems can be supplied as a plug and play. Where the complete system can be supplied fully working. The electrical box service is available from our distributors world wide

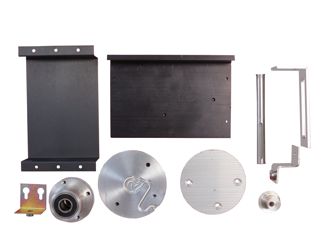

Cables, Sensors, Brackets, Motors

Controller Cables, Sensors and Wiring

Custom cable and wiring kits are available for OEMs and for any application.

Mechanical components, Pulleys, mounting brackets etc

Part of a complete service is the provision of a fit and forget service. Custom kits can be supplied with Motor Mounts, belts and pulleys which can be supplied ready machines to suit the client application.

Custom Servo Motors

Custom servo motors are available with a range of servo motor options, there many options including using an existing DC motors, DC servo or Brushless servo

- 600 Watt DC servo (1.7 nM)

- 800 Watt brushless Servo

- 1000 Watt brushless Servo

- 1500 Watt brushless Servo

- 2500 Watt brushless Servo

Hardware, software, Verilog, circuit board and Mechanical Design Services

Hardware Design

With many years of experience in the design of electronics hardware, ranging from semiconductors, white goods, Medical devices, control systems, temperature controllers, instrumentation etc.

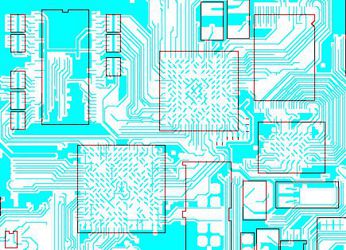

Printed Circuit Design

Using computer aided design TRM can design circuit boards up to 32 layers, for all types of product from radio, micro processor, analogue, power etc.

Mechanical Design

Using 3D cad mechanical design services include, Motor mounts, brackets, enclosures, custom parts for machines, load cells, MMI and displays.

- Brackets and motor mounts

- Supports and plates

- Cabinets and casings

- Custom plastic parts

- Actuators

- Encoders and sensors

Custom controllers for industrial systems, design, develop and Manufacture

Custom controllers provide the most cost effective and professional way for an OEM to effect machine control. Custom controllers can be used for almost any application such as machine tools, catering equipment, ovens, presses, depositors, bending machines etc. TRM has been designing and manufacturing industrial controllers for more than 22 years, no matter what your requirement is please ask, the chances are we can help. Our controllers can be used in almost any automation process, we get involved in the control of process that involve controlling Motion, Current, Voltage, Temperature. Our standard controllers include a digital recorder that can be set up with up to 8 channels. We make interface boards which include inputs for thermocouples, platinum resistance, load cell, TTL digital there are also 0 to 20 milliamp. Weather you are a OEM, machine renovator, scientific instrument company or you want to automate, we can help! Please call us.