Initiative Automation, CNC and Motion Control solutions

VIONiC™ series, a new family of ultra-high accuracy, incremental encoders.

Designed for the world's most demanding motion control applications, this development brings together Renishaw's renowned filtering optics with a new custom interpolation and monitoring ASIC (Application-Specific Integrated Circuit) that enhances dynamic signal processing and improves signal stability. This achievement has allowed Renishaw to create its highest performance incremental encoder system so far, at the same time combining all necessary interpolation and digital signal processing inside the read head to eliminate the requirement for additional external interfaces.

The VIONiC range has been designed to reduce overall system size to the minimum achievable for a high-performance system, whilst delivering class-leading performance in terms of cyclic error, jitter and accuracy. Customers can choose between two VIONiC read head variants. The standard VIONiC read head features a Sub-Divisional Error (SDE) of <±30 nm, a range of available resolutions from 5 µm to 20 nm, and speeds beyond 12 m/s. Alternatively for the most demanding performance requirements, customers can select VIONiCplus™ with best-in-class SDE to <±10 nm, low jitter to 1.6 nm RMS and resolutions from 100 nm down to 2.5 nm. Low SDE encoders are essential to minimise velocity ripple, which is important in constant-velocity applications such as laser scanning.

VIONiC series encoders are available with the same linear and rotary (angle) scale ranges as the TONiC™ series, such that existing customers may choose to install VIONiC as a drop-in replacement. Available scale types include metal tape, spar, and rotary rings (including ultra-high accuracy REXM). All VIONiC scales come with customer selectable IN-TRAC™ reference marks embedded in the incremental channel and dual-limit switches in the case of linear scales.

World leading research from Staffordshire University

February 2016

Staffordshire University successful research to help in the management of diabetic foot

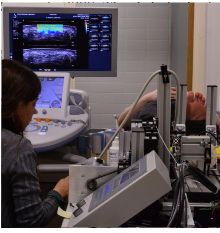

The Biomechanics team at Staffordshire University is focused on utilising biomechanics to enhance the clinical management of diabetic foot. For this purpose a novel in-vivo mechanical testing device was developed to enable the in-depth study of the biomechanical characteristics of the soft tissues of the diabetic foot. This custom device combines medical ultrasound and dynamometry to enable real-time imaging of the soft tissues of the foot during mechanical testing.

Full story can be read in next months news letter

Automation enhances quality and reduces costs

Automation has many benefits including enhanced safety, consistent quality, reduced manufacturing cost and ease of manufacture. Some companies however find the technical side can be daunting, we are here to help your automation plans come to fruition. The Automation Manufactures Alliance is a group of UK manufacturers working together to assist companies with general automation right through to complex machine and motion control. This site is designed is designed to assist the reader to find the services they need on the relevant manufacturers websites. We are here to help we will try to get back to you within 3 working days, please use our services we want to help you