Universal control system for motion control, automation, instrumentation and general purpose control

The PMC4 is a high quality universal control system that includes a full PLC, Motion Controller, Display and Keypad, the front is splash resistant. The PMC4 is a very flexible and can be used for many applications such as CNC, process control, automation, motion control or to replace a PLC. The PMC4 comes with the programming language MAP, the easy to learn programming language. For those who are not able to program there is a template design service and programming services.

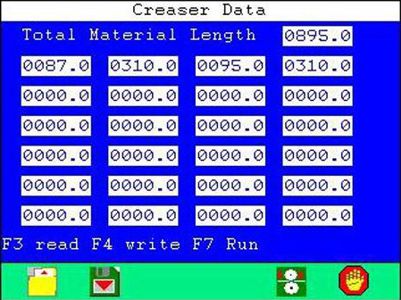

The PMC4 motion controller is used in many applications, from Grinders to process controllers, CNC to instrumentation. ProCut is an application designed for paper and metal cutting guillotines, it allows the operator to enter a cutting list via user friendly menus. ProCut has automatic features that make cutting labels and strips easy and quick to use, via dedicated menus.

- Separate power connection for the output drivers with up to 48 volts operation.

- 8 TTL outputs (for driving stepper motors etc).

- 8 High power drivers (up to 4 amps output) with protection.

- 4 Bidirectional inputs/outputs can be used as inputs outputs or both.

- Opto Isolated inputs can be set to TTL level or PLC (24 volt) style.

- 4 Analogue outputs gives +/- 10 Volts.

- 4 High speed analogue inputs +/- 2048 M.V.

- RS485, RS232 and CAN serial ports.

- 4 dedicated encoder inputs with Z pulses.

- USB port.

- 2MB of static battery backed memory.

- 64MB of DDR ram for running programs.

- 16MB of flash memory.

- Bright clear TFT display with 320 by 240 pixels, 65536 colors.

- Tactile keypad.

- Wide power options 7 to 32 volts (low power).

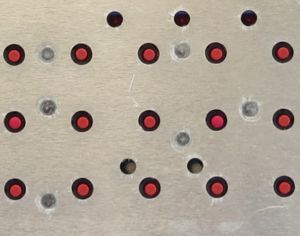

Splash proof keypad

- Quality durable tactile design.

- Reverse printed Polycarbonate front.

- Strong Aluminium front protects the key switches.

- Bright, easy to read and clean domed front .

The PMC4 keypad is easy to use, tactile and durable. The overlay is made out of polycarbonate, which is reverse printed so that the lettering can not wear out, the front is domed and this gives a quality feel. The front is easy to clean and chemical resistant. Durability is ensured by the use of a a strong back plate made from aluminum, this protects the key switches against excessive pressure. This design gives the keypad a quality feel with good tactility. Some controllers have been out for more than 17 years without any maintenance. The keypad also features 8 LEDs that can be used to heighten user awareness.

Durable Aluminium Case

- Durable powder coated 2mm Aluminium.

- Easy to panel mount, or pod mounting kit available.

- Good EMC shielding, supports D type connectors.

- Aluminium front provides excellent keypad.

The case of the PMC4 is made from 2mm durable Aluminium powder coated. This is not only durable, but it also provides excellent screening preventing EMC problems for the controller. The connectors are D type connectors, that are commonly available, reliable and cost effective. The case is designed to be panel mounted, or there is a POD that makes installing the PMC4 easy.

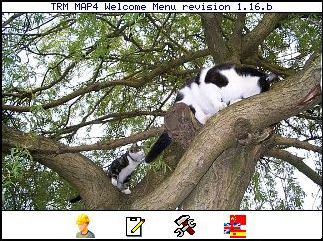

Bright clear photo quality screen

- 320 by 240 Pixel, Photo quality display.

- 65,536 colors.

- Crystal clear display, with polycarbonate window.

- Highly efficient, long life LED back light.

PMC4 supports a bright clear photo quality TFT screen. To ensure longevity the display has a LED back light, LED back lights provide a clear white back light that is very efficient. There is no need to use a screen saver with LED screens as in the majority of cases the display will last more than 10 years. New versions are planned soon with touch screen and more memory. The operating system supports many supports graphics and text display modes. This makes writing colorful and effect menus easier. Map exploits these facilities and supports easy of use.

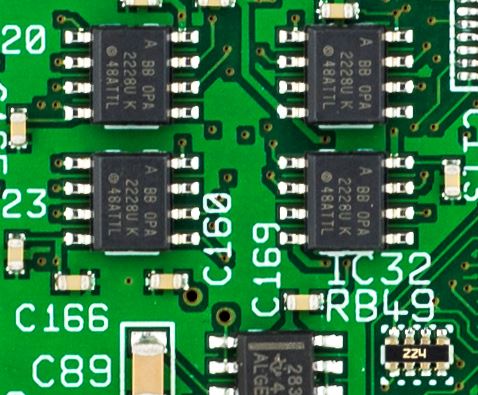

Advanced Hardware

- Flexible I/O designed in an FPGA.

- Large memory model, DDR, flash & static RAM.

- Highly efficient fan-less design.

- 8 layer board with surface mounted devices.

PMC4 features highly advanced electronics, the architecture is flexible and can be customized to suit applications. The CPU is a high power Coldfire device running at 160 MIPS. The drivers are MOS FETs that feature protection and can drive Contactors etc. directly. The circuit board is made from 8 layers and is built in our own factory, X-ray inspected.

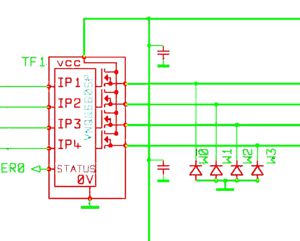

PMC4 Output Drivers

- 8 TTL (logic level) drivers.

- 8 High current drivers.

- 4 Bi-directional drivers.

- Volts free drive enable output.

The PMC4 has 8 TTL outputs, for driving stepper motors etc. 8 High current drivers with output protection that can directly control contactors, air cylinders etc. It also has 4 Output/Inputs drivers

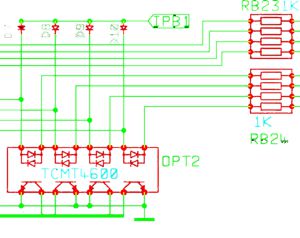

PMC4 Flexible inputs

- 4 Banks or selectable inputs.

- 16 General purpose Inputs.

- 4 Bi-directional drivers.

- 2 32 bit counters for jog encoders or pulse counter.

The PMC4 has a flexible input system. There are 16 inputs configured in banks of 4 of 4 inputs. These banks can be set as TTL style where the inputs are active low, this is designed to interface to encoders etc. TTL inputs are also faster (as the voltage is lower). When set as PLC style the bank of inputs become 24 volt active (like PLCs). Any input can be configured as a counter input or as a pair for jog encoders etc. There are also 4 inputs that are associated with the Bi-directional outputs, these inputs are PLC style.

Serial Ports

- Four wired RS 232 port.

- Two wired RS485.

- Controller Area Network (CAN).

- USB2 serial port for memory.

RS232 port with 4 wire, also supports 2 wire communications, supports 7 or 8 bit, baud rates up to 230.4 KBPS. RS485 offers multi-drop baud rates 50 to 230400 BPS. Controller Area Network(CAN)is used in many industrial applications and is error checked. USB host is supported so that the PMC4 can read flash sticks etc. There is an expansion port that can be used to connect to external serial connected interface card this uses SPI.

Dedicated Encoder Inputs

- Four dedicated four wire encoder inputs.

- Each channel has a Z pulse input.

- High performance inputs (over 1 MHz).

- Voltage Tolerant differential inputs.

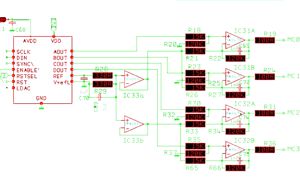

Analogue Inputs

- Four channel ADC with +/- 2048mv range.

- Very high speed conversion.

- Very high input impedance.

- Easy to implement 0-20ma or 4-20ma inputs.

Analogue Outputs

- Four channel DAC with +/- 10V range.

- Very high speed conversion.

- 16 Bits resolution.

- Stable precision outputs.

Multiple flexible Timers

- Multiple Hardware timers with interrupt.

- 1 Us tick timer, (32 bits).

- 8 timers are available to MAP.

- Programmable up/down timers.

Software options for the PMC4

Software Options

- MAP is an easy to use programming language.

- Custom written program an EXE.

- G code for CNC applications.

- Software templates.

MAP programming Language

- Easy to learn programming language

- 117 MAP commands some with 12 options.

- Fast, predictable, precise programming.

- Full PLC included, without scan time.

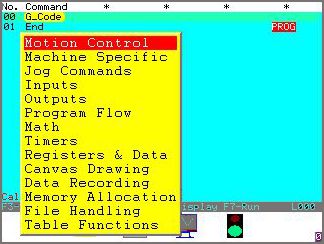

Map is a easy to use programing, which can be programmed either on or off line. Programs can also be written in G Code and imported into MAP. This makes it easy to use the advantages of both systems. To make programming easy, commands are in groups, there are 14 groups.

CNC capable

- G Code interpretor include in MAP.

- Import and mix G Code with MAP.

- Options for Milling machines, lathes etc.

- Import G code as a program.

MAP software is G Code compatible, that can be used for lathes, Routers, Laser cutters, Grinder, milling machines Etc. MAP a flexible language that can include G Code or G Code can include MAP for G Code++. The above image shows a large G Code file of more than 43,000 moves of G Code, for making shoes implants. Map allows nesting and other features that make G Code applications quick and easy to implement.

Programmable Logic Controller

- Easy Inputs & Outputs controls

- Fast precision analogue inputs & outputs

- No Scan timer constraints

- Maths and motion control

MAP is designed to offer a complete solution for machine or process control. MAP now supports many of the commands that make PLC programs very easy to implement. There are special commands that process inputs, the output ports are also easy to manipulate, because there is no scan cycle like traditional PLC's have. The memory model is flexible and memory can be allocated allowing the controller to implement probe and store applications applications. Mixing PLC, maths, memory, input, output, motion control functions makes implementing difficult PLC applications simpler.

Mounting options for the PMC4

Door or Panel Mounting

- Easy to panel mount the controller.

- Mounting brackets provided.

- Mounting gasket

- Easy to make a slot in panel.

Mounting POD

- The POD makes mounting the controller easy.

- Can be mounted on an arm.

- Made from powder coated Aluminium.

- Pre-punched holes for stop/start switches.

Universal control system, Motion control, automation, CNC, PLC & Man Machine Interface, the PMC4

The PMC4 is a general purpose controller for CNC, Motion control, Automation, Process control, Instrumentation and general control. PMC4 has a flexible design and is easy to customize for challenging applications. PMC4 can be used to control a complete process it has a full PLC, motion controller and Man Machine Interface. The PLC is fast and flexible, it can catch pulses that are micro second fast. This makes the PMC4 the perfect choice for many applications, like flying saws, guillotines, depositors, welders, drilling machines, custom machines, process control and many more applications.